Aug

21

2013

Chassis Torsion

The chassis has to be able to flex a little, so it cannot be bolted directly to the canopy, as flexing the canopy will crack the fibreglass wall sheets.

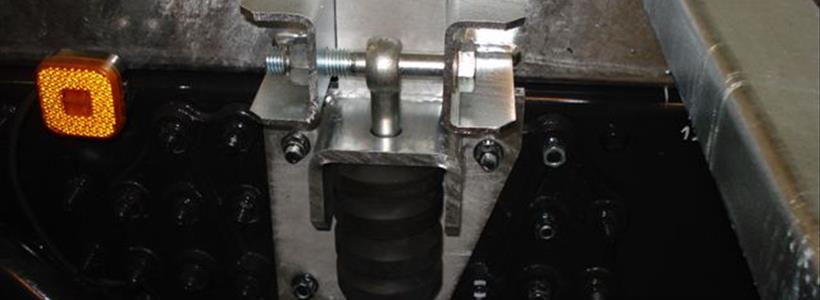

Unimogs solve this by making a completely free pivoting frame, which transmits no torsion up to the canopy, but it adds 200mm to the height of things so the whole canopy sits higher:

Uni-Cat also build their trucks this way.

For our build, it will be something similar to this:

The body builder has good experience building offroad mining exploration vehicles, and this is their preferred method of attachment. So that’s what we’re going with!

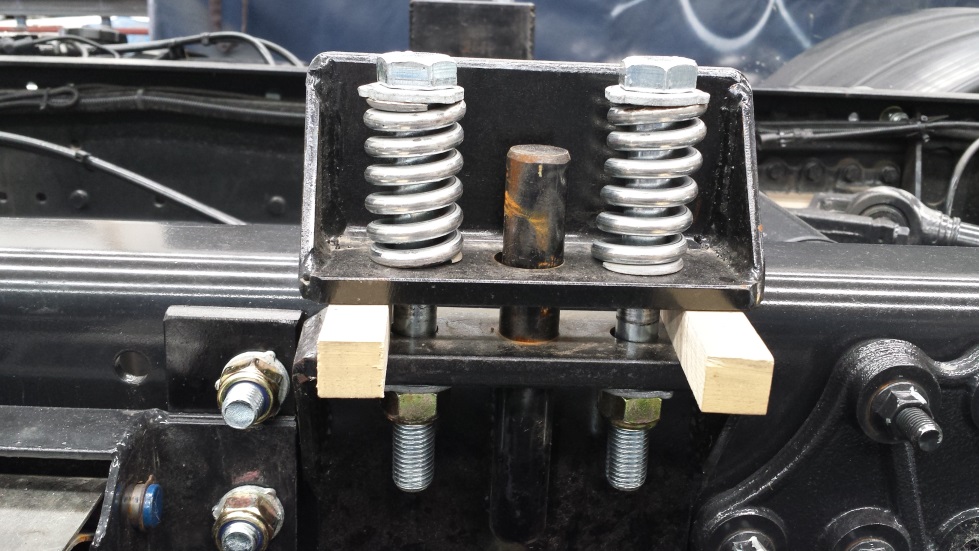

Update: This is the prototype fitting that we will be using. A central locating pin, and 2 springs either side. The 2 pieces will be separated by 20mm before welding onto the frame.

Update 2: This is how they are set up with the springs and bolts attached.

The wooden spacers just hold the top plate up while things get welded into place, so there is space for some movement between the brackets when things start getting flexy!

Next post ...