Mar

16

2015

I like the idea of something that can be used for more than one purpose, so when it came to building an outside table I thought it would be good to think laterally, and base it on a solar panel! That way we could use it to generate power for the 12v batteries when it was not being used as a table.

The base for the table is a 135W Kyocera panel. It's not especially light (at 12Kg) but it's not stupidly heavy either. We wanted something that four people could eat from comfortably, for when we have friends along for the ride.

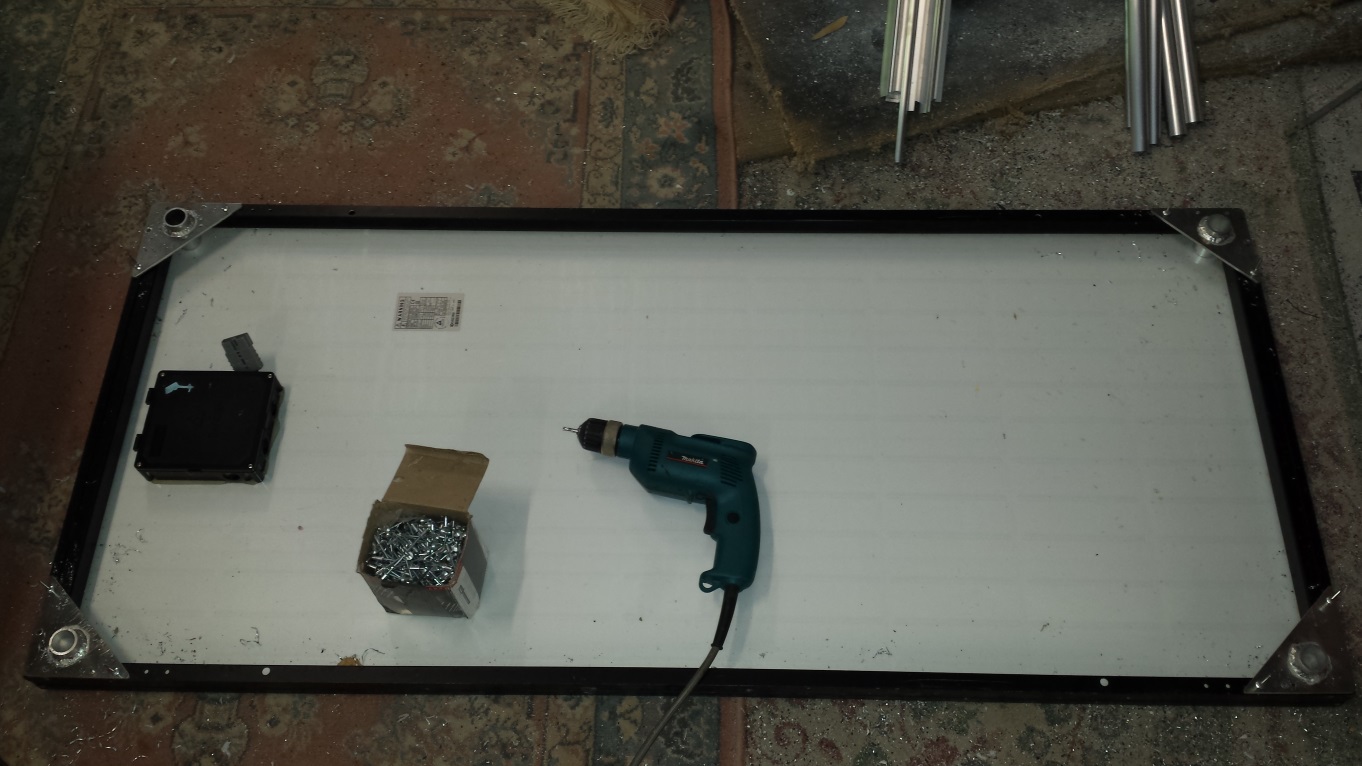

The first thing to do was to whip up some legs, so that involved building a bracket on each corner.

Do this four times and you end up with this:

That turned out to be the easy part, because finding two aluminium tubes that fitted snuggly inside each other was not happening. I could get thin walled alloy (1.2mm) that was a lovely tight fit, but it was too thin to hold the weight of the table. The 3mm tube was strong enough but there was a 2mm gap between the tubes which meant the legs were extremely wobbly,

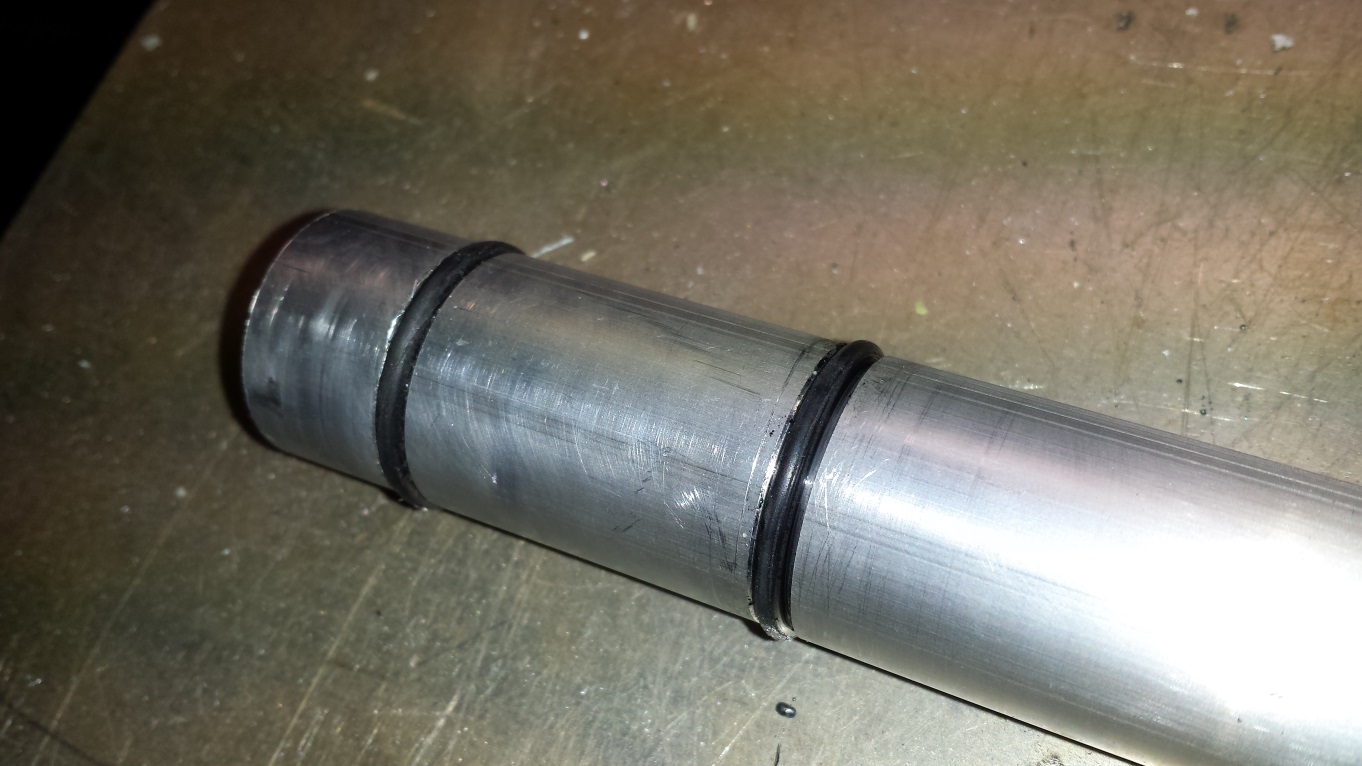

The first idea was to insert 2 O-rings top and bottom on the legs to pack out the gap. So I threw the legs onto the lathe and cut out a couple of grooves for the O-rings, like this:

Here they are with the O-rings fitted:

This took up a lot of the slop, but of course rubber O-rings are still flexible, and the table top wobbled way too much for my liking.

The next idea was to pack out the top of each leg with some heat shrink, but again this was not hugely successful as the heat-shrink still moved around a bit.

After a day of doing other things, I came back with the idea of TIG welding some beads to the top of the legs and then cutting them down to the right diameter in the lathe.

I put 3 beads down the sides, and then cut them back so they fitted very firmly into the socket part.

That made the table nice and solid, so after three goes at the legs, the table was finished.

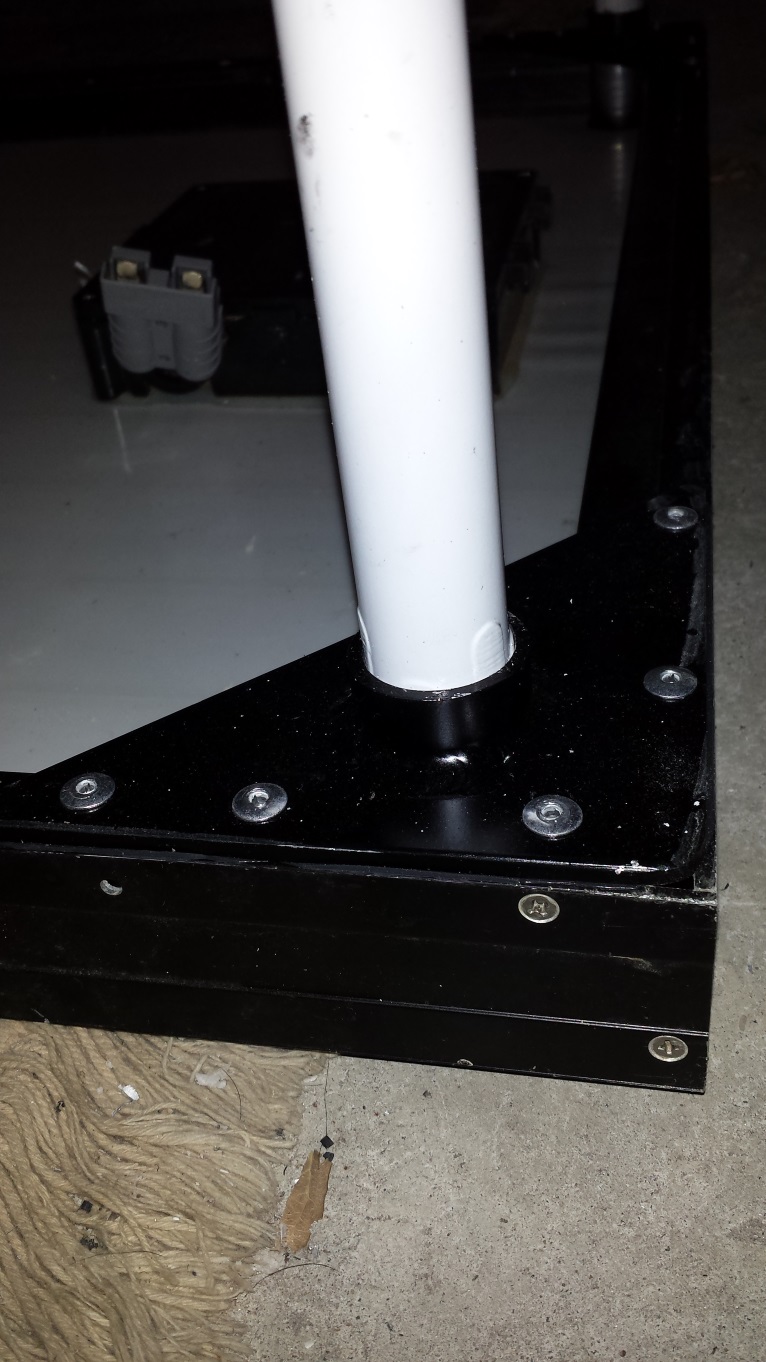

The brackets got painted black, and the legs white.

The brackets got painted black, and the legs white.

For feet, I got rubber tips like you get on a pair of crutches. They have a bit of give in them to mold to uneven surfaces, and they won't sink much into sand either.

In the mid-left of the photo you can see the Anderson plug which connects to the leads to the MPPT controller on the batteries. It only takes a second to connect/disconnect.

And there we have a table that can be used to top up the fridge battery! It's almost wobble-free, and it's strong enough that I can sit on it (although I only weigh 74Kg / 160Lbs).

I've got quite a long power lead, so I can leave the truck in the shade, but put the panel out into the sun.

Next post ...